Our company has been specialising in the manufacture of plastic moulds since 1999 with premises located in Reguengo do Fetal, Batalha, comprising over 1000m2. We work for the economic, car, household appliances, medical, electronic, and other sectors.

The secret of success for almost two decades working has been based on constant innovation supported by a team whose work alignment, motivation, and updated know-how are achieved by means of a weekly brainstorming.

We have a modern industrial complex, which comprises several types of machining, electrical discharge, hole boring, overhaul, and measuring equipment. Click here to learn about all the types of equipment.

With a team of 30 employees who are widely experienced in mould engineering, we can guarantee competitive bids.

The mission of Sá & Vieira is to provide a large service in the manufacture of moulds executed and supervised by extremely experienced technicians from: project design, manufacture, testing, pre-series, export, and follow-up at the client.

Learn about our project stages and what they involve by clicking here.

We are widely experienced in large mould engineering for the plastic industry. Here, at Sá & Vieira there are employees with over 20 years of experience in this area, who render each project simpler, faster, and with more quality.

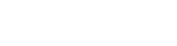

Sá & Vieira stands out due to its technical quality and the solutions it offers clients in order to optimise the entire productive process and end product. Moulds go through a strict quality test, so that when they get to the test stage, there are no errors making them go back to the production stage.

OUR DEPARTMENTS

- Sales

We are a partner for our clients, and that is why we have uplifted our level of communications with them.

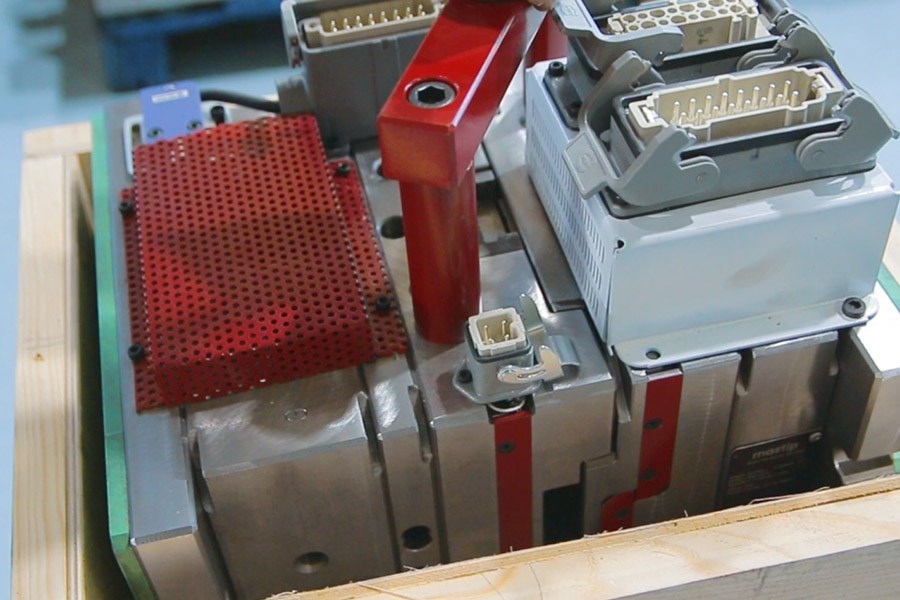

- CAD / CAM

2D design and 3D Surface Modelling.

- Production

Manufacture and Projection of moulds for plastic injection moulding.

- Quality

From employees to the equipment, we have undertaken a serious and highly responsible commitment to the product’s quality.